Introduction to Demand Controlled Ventilation (DCV) Systems

Modern airtight buildings require good ventilation. Variable Air Volume (VAV) systems allow changing of the air volume. Sometimes central units which have means for controlling the ventilation speed are referred as Variable Air Volume systems. But it does not mean that every time every room will be ventilated according to the need. Still, some rooms may be over ventilated and some rooms under ventilated.

Best possible ventilation is guaranteed with Room based Demand Controlled Ventilation system, a type of HVAC (Heating, Ventilation, and Air Conditioning) solution designed to provide precise and energy-efficient ventilation control for every room.

VAV systems can adjust air volume based on pre-defined settings, manual settings or even have separate zones with dampers or valves, allowing independent control for better comfort and reduced energy use. Unlike constant air volume systems that deliver a steady airflow regardless of demand, and VAV systems that can adjust air volumes, DCV systems adjust the amount of air supplied to every room based on real-time indoor air quality requirements. These systems are commonly used in commercial buildings where load conditions vary throughout the day. It has remained typically for the commercial use, due to the cost reasons.

Aerefy valves have substantially reduced the cost of building room-based Demand Controlled Ventilation systems both for new and existing buildings and making it a viable choice also specifically for the hotels.

Fig 1. shows typical damper installation of the DCV, where both supply and exhaust ducts are fitted with the actuator, damper, silencer, control unit and the room sensor. This setup requires 5-8 components per each room, which is very expensive to build and also difficult to maintain and service whereas Aerefy has only 1-2 components reducing risk of failure and complexity.

Fig 1. Damper with actuator between double ceiling for a typical installation.

Typical VAV system intends to control both fresh air supply and removal of the contaminated air in perfect balance within one section.

How typical DCV works?

- The first step is to be able to measure indoor air quality in each zone. There are several contaminants that are harmful: Particulate matters, Volatile Organic Compounds, Carbon Monoxide, Radon, Biological Contaminants (Mold, Dust Mites, Bacteria, Pollen), High concentrations of CO2. Typical sources of the contaminants are people, furniture, stoves and fireplaces, paints, cleaning agents, building materials, candles and cooking. Most typical sensors measure VOC, CO2 and Humidity. Radon levels have to be measured and taken into account during ventilation planning phase.

- Based on the actual measurements each room equipped with motorised dampers or valves shall have the extract and supply air volumes regulated dynamically to keep the measured air quality parameters under defined levels.

- Central unit must regulate the supply and exhaust air volumes according to the need of the total system.

These three steps comprise of the full DCV system.

How DCV is done with Aerefy?

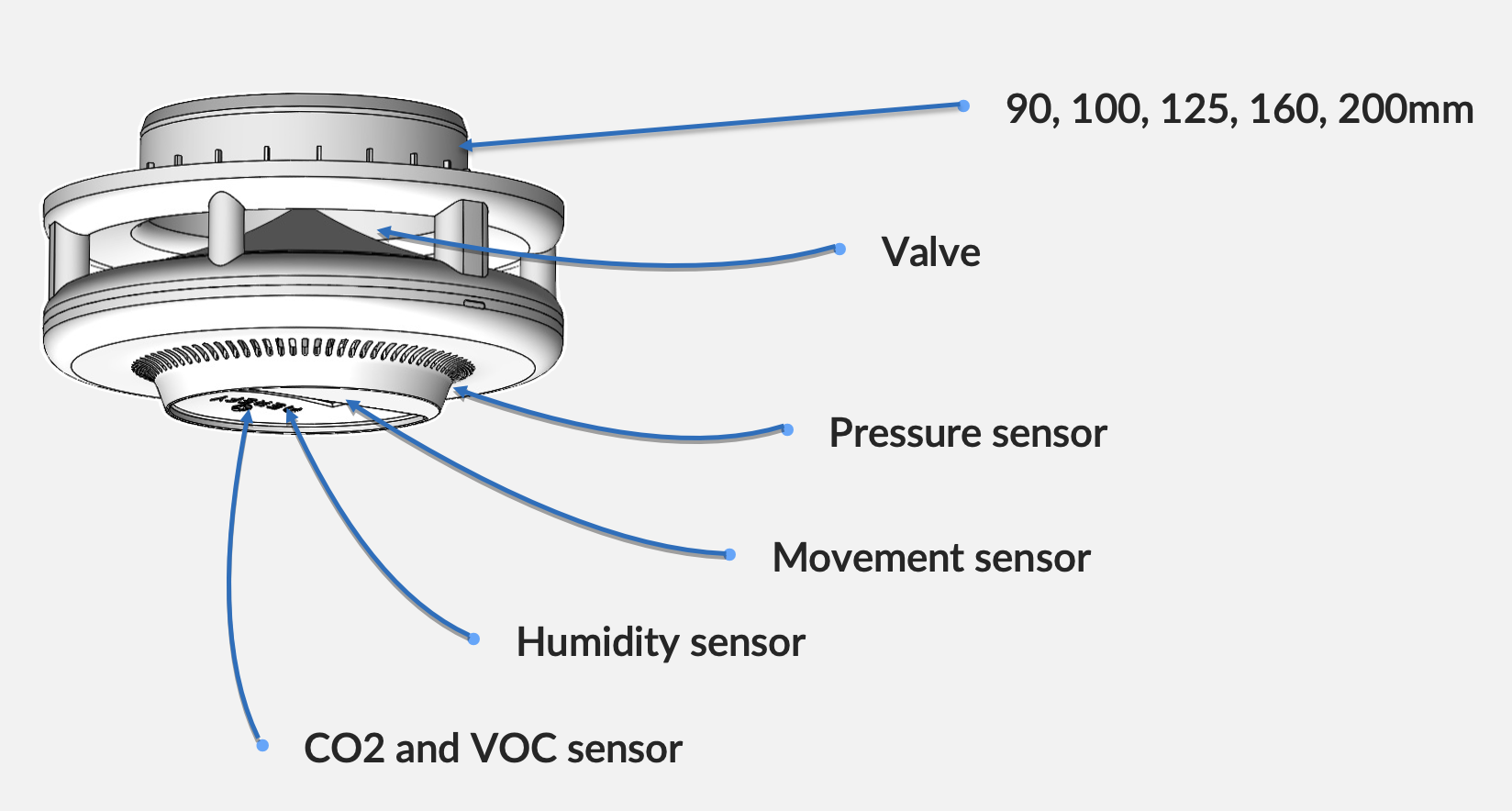

Aerefy has inbuilt sensors in every valve. Therefore all areas of the building are covered with the sensors and even smallest changes in indoor air quality are detected. Smart valves will intelligently react to movement or changes in air quality. Therefore only contaminated air is extracted.

Fig 2. Aerefy exhaust valves with integrated sensors.

Valves cover the duct sizes from 90mm to 200mm and for larger ducts dampers with actuators are used. Aerefy valves and dampers are only installed on the exhaust ducting with the purpose of removing contaminants from the building, closest to the source of contamination in the most effective manner. Fresh air supply is controlled by the exhaust valves by the means of pressure balancing at the supply duct and the balance between fresh and exhaust airflows is kept constant at the central unit.

The Aerefy advantage when compared to traditional DCV design comes from the system design and components. Valves have inbuilt sensors and is equipped with local intelligence, therefore expensive central control systems for keeping the air supply and exhaust volumes equal in every room is not required. Where traditional systems require up to 5-8 components per each room, Aerefy only needs 1, giving huge cost advantage.

Fig 3. Aerefy DCV valve for duct sizes 90-200mm.

Measurements and calculations show that properly built DCV can save around 40% of heating and cooling energy while assuring quality of indoor air.

Shall Heating or Cooling be integrated with ventilation?

Air has low heat capacity. Therefore it can not hold much energy whether warm or cold. That means you need a lot of air to carry the same amount of heat that a small amount of water could.

If indoor air quality is good, but temperature needs adjustment, using air to cool or heat the room adds up the costs and complexity. Simply put, why to move around large quantities of air if there is no need for more ventilation?

Therefore, when planning new buildings, using large surfaces like floors for radiant heating and radiant cooling panels in ceilings gives the best overall comfort. If faster reaction times for sudden temperature hikes shall be achieved, then slight cooling of the supplied air can be considered.

It is very important to avoid higher airspeeds and large temperature differences as this creates feeling of draft.

It is always good idea to use radiant heat or cold for the best overall performance and comfort.